Product details

Description

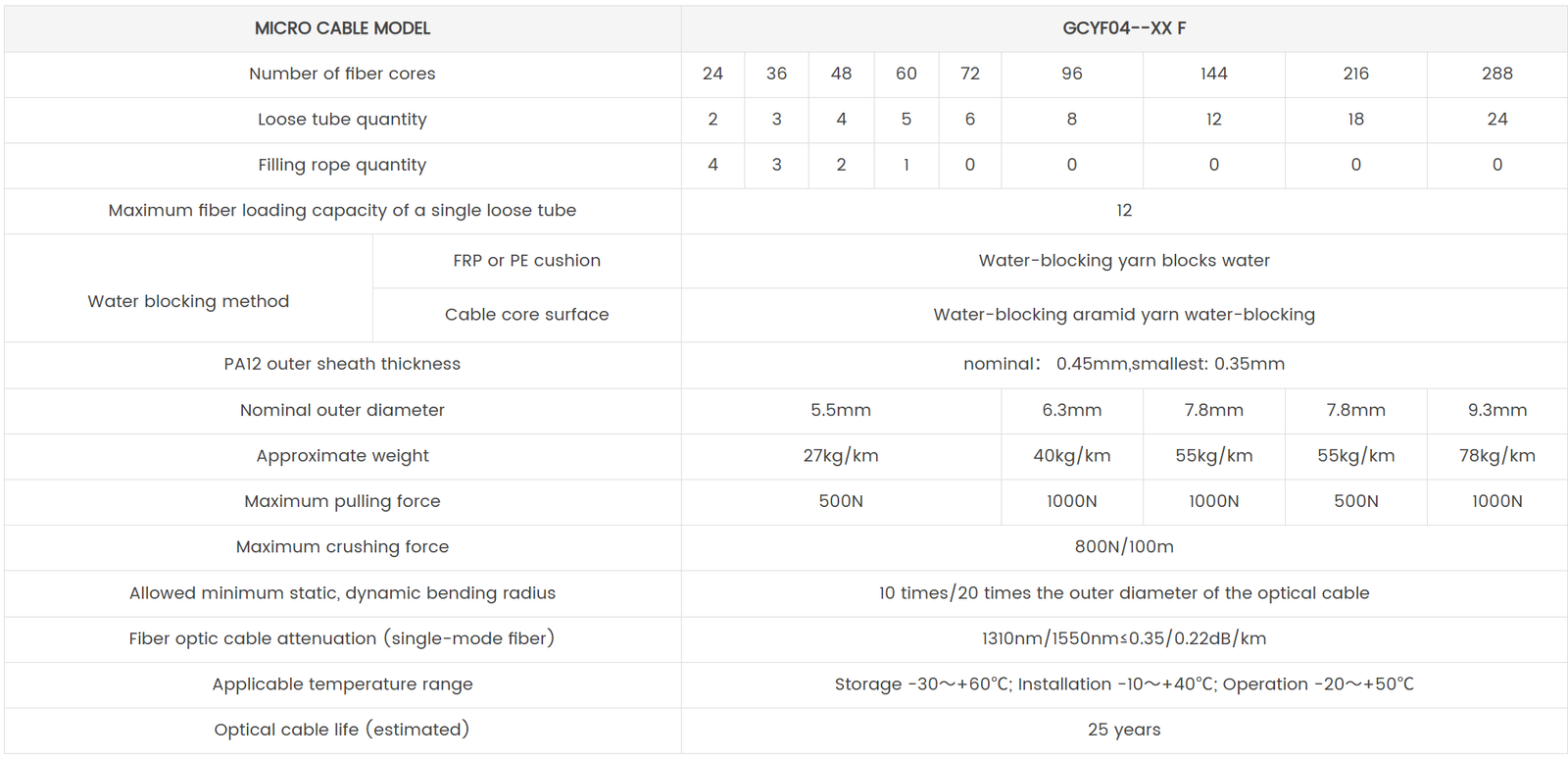

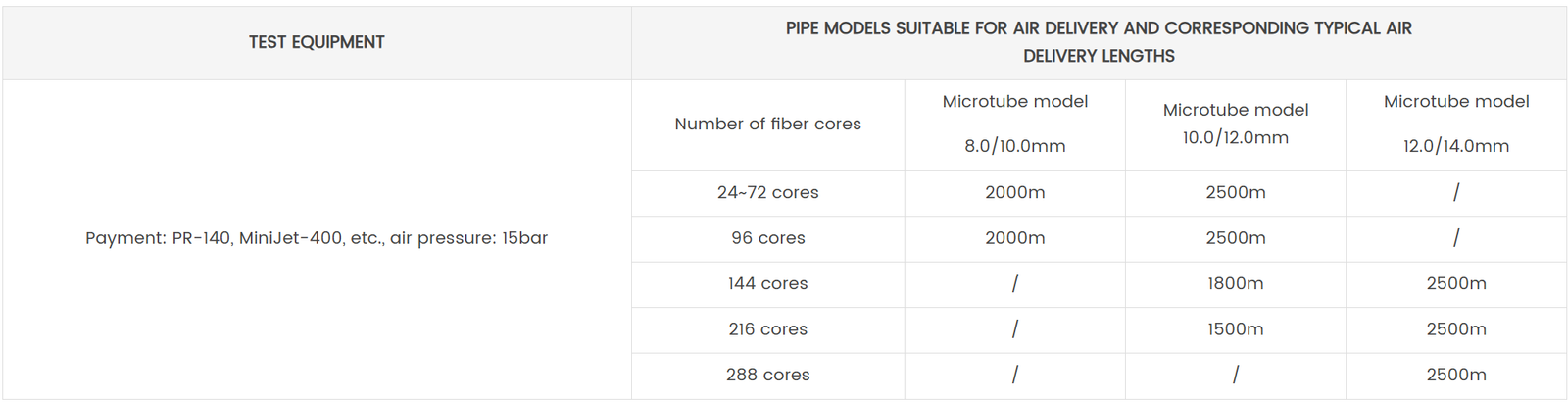

Air-blown micro cables use air-blown laying methods to connect optical branch points and user access points. The optical cable has good mechanical and temperature properties, high tensile strength guaranteed by fiberglass, good flexibility, easy construction, and low cost..

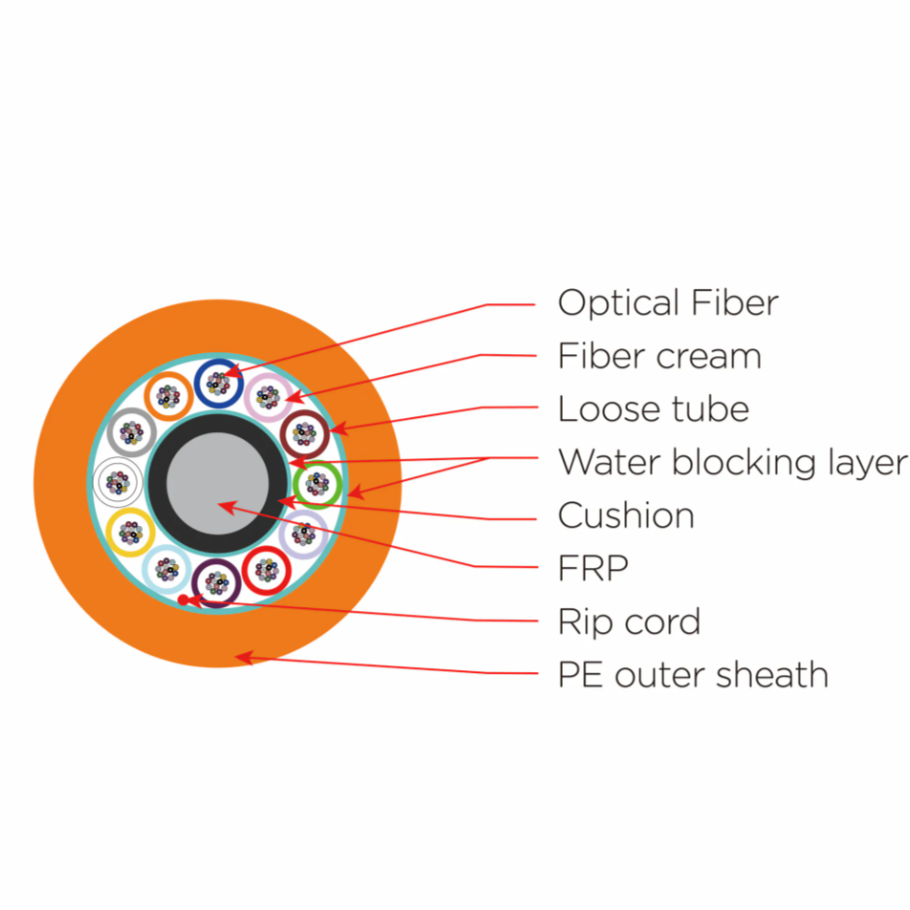

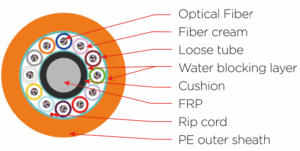

Cable section construction:

Product features:

- Structural optimization design, with the best fiber capacity.

- The remaining length of the optical fiber is precisely controlled and the performance of the optical cable is stable.

- Dry cable core blocks water, is low-carbon and environmentally friendly.

- Innovative design of the sheath surface enhances air-blowing performance.

Product application:

- Air blowing installation.

- Core network.

- FTTx network.

- Backbone network